QUALITY AND GOOD PRACTICES

MDH Laboratories’ quality control begins with the acquisition of superior raw materials that meet the highest American and European standards related to the pharmaceutical-grade manufacturing industry.

The development and production process is carefully monitored. Each step of the manufacturing process is verified by reviewing compliance with safety measures and regulated standards in the pharmaceutical industry.

Once the products are manufactured, each batch undergoes rigorous laboratory testing to ensure that each product meets the exact required specifications. Our products are also subject to random quality testing to ensure their quality. The test results are publicly shared so that consumers can clearly understand the product they intend to purchase.

CERTIFICATES OF ANALYSIS

These are official documents issued by MDH LABORATORIES and serve as evidence that the product has undergone quality testing and is within acceptable limits for use and commercialization.

These documents detail the results of tests and analyses conducted on a specific product sample. They provide detailed information on the composition, purity, concentration, and quality of the product, verifying that it meets the required standards and specifications. You can download the certificates for each product in our PRODUCTS section.

HEAT SEALING FILM:

We use high-quality shrink films that provide protection against external agents such as dust, moisture, and other contaminants. These films shrink when exposed to high temperatures, allowing them to fit perfectly to the shape of the container.

PRINTED CAPSULES:

Each capsule is engraved with the MDH LABORATORIES logo, which is a sign of authentic and high-quality products.

IMPORTANT: This security measure applies to batches produced from June 2023 onwards.

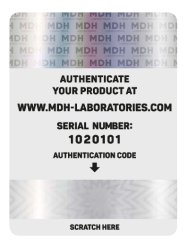

ANTI-COUNTERFEITING MECHANISMS

Unique s erial number: All injectable, capsule, or tablet products have a unique serial number that can be verified on the company’s website, ensuring product authenticity and complete traceability.

Induction sealing liner: This type of seal will eliminate product leaks, provide security by preventing tampering, contamination from external agents, and extend the product’s shelf life.

MANUFACTURING PROCESS

MDH Laboratories is committed to continuous process improvement and ensuring that our manufacturing is in appropriate sanitary conditions, supported by our ISO 9001:2015 – Quality Management System and Good Manufacturing Practices (GMP) certifications.

ISO 9001:2015 – The Quality Management System ensures that our performance is focused on continuous improvement and that our supplied products meet the needs of their users.

GMP – Good Manufacturing Practices. It guarantees that our products are manufactured under appropriate sanitary conditions, reducing inherent risks in production and distribution. At MDH, we ensure that optimal sanitary conditions are met in all facilities that house the products throughout the production process until they reach the public for sale: factories, distribution channels, sales points, and/or marketing. This way, we ensure that they are suitable for human consumption.